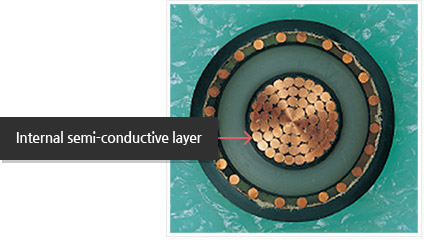

Internal Compound

본문

-

For semi-conductive used to minimize electrical stress on high voltage cables lower than 35kV such as MV power cable. Excellent surface smoothness and excellent long term performance of extrudability.

Application

- 1. Semi-conductive compound used for the internal semi-conductive layer in high voltage cables lower than 35kV such as MV power cable

- CN/CV, TR-CN/CV, URD CABLE, FR-CN/CO, TR-CN/CE

-

Features

- Excellent surface smoothness

- No discoloration

- A very stable volume resistance

Major physical properties and process temperature

| GRADE | WS-701HL-1 | WS-707 | TR-709 | WS-706R | |||

|---|---|---|---|---|---|---|---|

| Description | Bonded Type | Bonded Type |

|

Bonded Type | |||

| Application | Conductor shield For Outdoor Cable |

IEC 60502 Up to 35KV |

TR-CN/CV Up to 35 KV |

IEC 60502 Up to 35KV |

|||

| Physical Properties (Mean Values) | Test Method | Units | |||||

| Density at 23℃ | ASTM D1505 | g/㎤ | 1.14 | 1.13 | 1.12 | 1.14 | |

| Tensile Strength | ASTM D 638 | Kgf/㎟ | 2.1 | 1.7 | 1.8 | 2.0 | |

| Elongation at Break | ASTM D 638 | % | 210 | 170 | 230 | 190 | |

| After aging (135℃×168hrs) | T·S | ASTM D 638 | % | 96 | 105 | 107 | 89 |

| E·B | ASTM D 638 | % | 100 | 97 | 104 | 99 | |

| E.S.C.R 100% | ASTM D1693 | hrs | 〉200 | 〉200 | 〉200 | 〉200 | |

| Brittleness Temperature | ASTM D 746 | ℃ | -40 | -40 | -40 | -40 | |

| Heavy Metal Content | ICP | ppm | - | - | 〈200 | - | |

| Peel Strength | AZ/NZS 1660.2.5 | N | 20 | 32 | 45 | 60 | |

| Volume Resistance | 90℃ | ASTM D 991 | Ω·㎝ | 500 | 600 | 600 | 350 |

| Zone 1 | Zone 2 | Zone 3 | Zone 4 | Neck | Head | Die |

|---|---|---|---|---|---|---|

| 90 | 100 | 105 | 108 | 110 | 110 | 110 |

- Product characteristics shown above are only guidelines not the actual product specification.

- Process temperature conditions for the product may differ according to the technical spec of the machinery and processing condition.