Non-crosslinked PVC compound (ISO 6722 standard)

body text

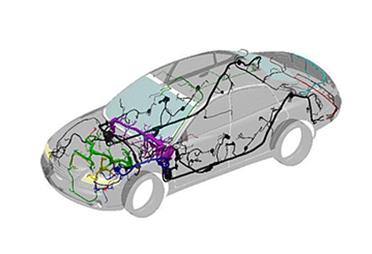

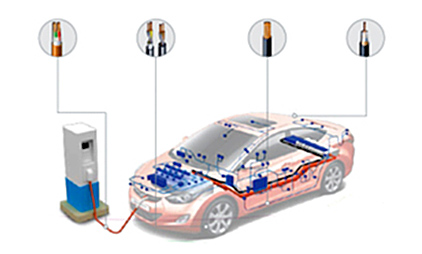

Application

- Insulating and coating material for automobile wire which meets the ISO 6722 standard.

Features

- Smooth surface

- Excellent property and workability.

- Free of RoHS (Pb, Cr6+, Cd, Hg, PBBs, and PBDEs) restricted heavy metal.

Major physical properties and process temperature

Test Item UNIT Value Test method FLRY-A FLRY T3PVC Room Temp. Tensile Strength Mpa 28 24 24 IEC-60811 Elongation % 280 320 320 Aging Test 1KV - PASS(110℃×240hr) PASS

(125℃× 240hr) PASS

(155℃×240hr) ISO 6722 Oil Test 1KV - PASS PASS PASS ISO 6722 Low Temp Resistance (-40℃) 1KV - PASS PASS PASS ISO 6722 Hardness Shore A 95 95 95 ASTM D 2240 Specific Gravity g/㎤ 1.33 1.33 1.32 ASTM D 792 Description ISO6722 ISO6722 ISO6722 Application FLRY-A Type FLRY-B Type

- Product characteristics shown above are only guidelines not the actual product specification.

- Process temperature conditions for the product may differ according to the technical spec of the machinery and processing condition.

PVC COMPOUND

| Grade | Workable Temperature | HYUNDAI | KIA | GM | Renault samsung | NISSAN | FORD |

|---|---|---|---|---|---|---|---|

| T1 | 75℃ | AV-SS/OD(A), CORD(OD)/A | T1 | ||||

| T2 | 100℃ | AV-X, T2 FLRY | T2 | ||||

| T3 | 125℃ | T3 | |||||

| T4 | 150℃ | ||||||