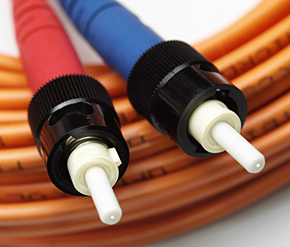

PE coating compound 2

body text

-

Application

- Power cable, communication cable coating compound.

Features

- Easy to extrude

- Excellent weather resistance.

-

Major physical properties and process temperature

| Test Item | UNIT | Value | Test method | ||

|---|---|---|---|---|---|

| WS-315 | WS-320 | ||||

| Room Temp. | Tensile Strength | Mpa | 16 | 24 | ASTM D 638 |

| Elongation | % | 550 | 550 | ||

| Melt index | g/10min | 0.63 | 0.28 | ASTM D 1238 | |

| Brittleness Temp | ℃ | -75 | -75 | ASTM D 746 | |

| Density | g/㎤ | 0.93 | 0.93 | ASTM D 1505 | |

| Carbon Black Content | Wt% | 2.5 | 2.5 | ASTM D 1603 | |

| Environmental Stress Crack | EA | 0 | 0 | ASTM D 1693 | |

| Dielectric constant @1MHz | - | 2.5 | 2.5 | ASTM D 150 | |

| Dissipation Factor | - | 0.001 | 0.001 | ASTM D 150 | |

| Description | LLDPE | LDPE | |||

| Application | Coaxial cable Sheath for LV,MV cable |

||||

| Zone 1 | Zone 2 | Zone 3 | Zone 4 | Neck | Head | Die |

|---|---|---|---|---|---|---|

| 185 | 190 | 195 | 200 | 200 | 210 | 210 |

- Product characteristics shown above are only guidelines not the actual product specification.

- Process temperature conditions for the product may differ according to the technical spec of the machinery and processing condition.